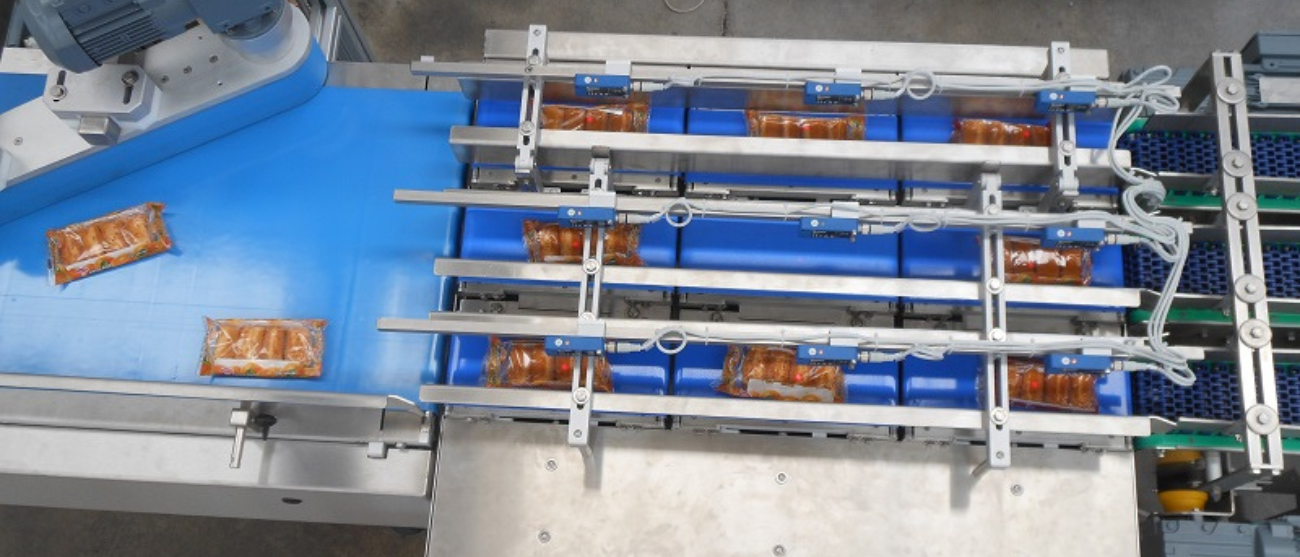

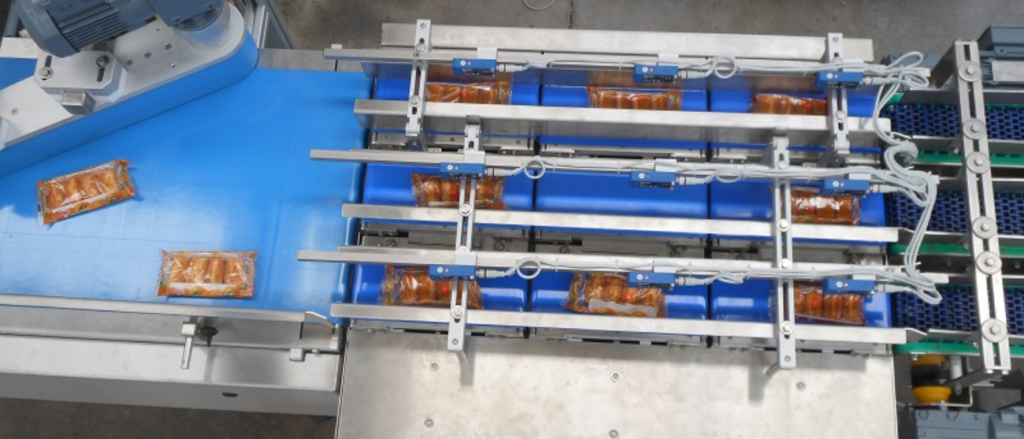

It is necessary to insert a belt merge, which indicates that we’re working with a packaging line with a high degree of complexity and automation.

Process optimization is the goal, improving the packaging machine’s performance. But if you install the “wrong” system, you risk the opposite effect of having to contend with regular unplanned downtime.

When it comes to dynamic belt merges, we at MH have developed the HP dynamic system that can reach manufacturing of 600 ppm for 150mm flowpacks.

This system includes one-by-one timing of the items, created using a multi-belt system with independent power for each of the entry lanes. The machine’s control system enables oversight of the step between the packaging coming out of the system and ensures that the timing occurs without contact, removing the risk of jams, overlaps or damage.

![]()

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.