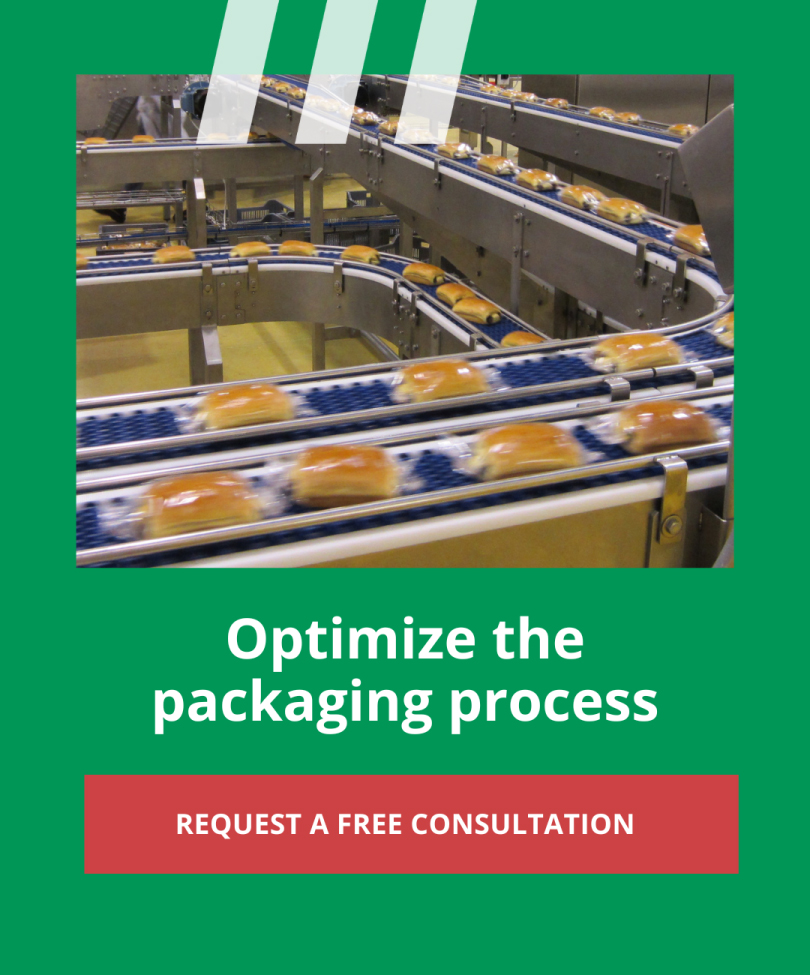

When it comes to optimizing efficiency in modern production layouts, one solution makes a real difference: the spiral conveyor.

Compact, versatile, and tireless, the spiral is one of the most effective technologies for utilizing vertical space, streamlining flows, and ensuring operational continuity—even in the most complex plants.

But be careful: not all spirals are the same.

To get the most out of your line, choosing the right spiral is essential—and the details make all the difference.

Which spiral is better? It depends on your needs:

- Tabletop chain spiral → ideal for high-speed, compact layouts with packaged products

- Modular chain spiral → perfect in environments requiring sanitization, frequent washdowns, and the handling of unpackaged products

Transported materials, hygiene requirements, cleaning frequency, available space: every plant is unique.

In this post, we guide you step-by-step through the key technical and practical differences, share a real case study, and help you identify the perfect spiral for your packaging line.

Tabletop Chain Spirals: Maximum Efficiency, Minimal Footprint

Tabletop chain spirals are designed for durability and consistent performance, even at high speeds. Equipped with roller bearings that increase load capacity and strength, they’re ideal for:

- Packaged products with minimal sanitation requirements

- High-speed applications requiring continuous flow

- Compact layouts with space constraints

- Product flow from primary packaging to palletizing

If you’re looking for maximum efficiency in a compact layout, this is the spiral for you.

Our collaboration with Ambaflex has proven the reliability of this technology—delivering top performance and optimized design even in space-critical settings.

However, be aware: this is not the right choice for environments that demand high hygiene standards.

Modular Chain Spirals: Sanitization and Flexibility

In more sensitive environments, where cleaning is a priority, modular chain spirals provide a key advantage.

Made from food-grade certified materials, they ensure:

- Enhanced hygiene and cleanability

- Design that minimizes product and water retention

- Compatibility with unpackaged products

- Seamless integration with ovens, freezers, or coolers

This is the ideal choice for clean rooms, post-process zones, or areas with frequent washdowns.

The Most Advanced Solutions?

Our partner Intralox offers multiple advanced options, including:

- OverDrive – Ideal for mixed environments with semi-packaged products and freezer exits

- SideDrive – Offers greater layout flexibility and high washdown capability

- DirectDrive – Optimized for extreme environments, including sub-zero temperatures

Thanks to our partnership with Intralox, we’re licensed to build OverDrive and SideDrive spiral systems for our applications.

The Right Choice Comes from Real Needs

There’s no “one-size-fits-all” spiral—only the one that best fits your plant.

If you handle packaged products and need speed, compactness, and reliability, the Ambaflex tabletop spiral is a great solution.

If your environment requires frequent washdowns or delicate product handling, the Intralox modular chain spirals offer top-notch safety and hygiene performance.

A Real Case: When Hygiene Is the Priority

Let’s get practical.

One of our clients needed to install a spiral conveyor in a clean room with frequent washdowns—even though the food products never made direct contact with the conveyor.

Here, the priority was minimizing water stagnation and ensuring rapid, effective cleaning.

The solution?

A modular chain spiral, built for hygienic environments and low maintenance. A system that delivered safety, reliability, and long-term performance.

Need Help Choosing the Right Spiral for Your Line?

Let us help.

With our MH Scan Solution, we offer a free technical check-up of your production line. We’ll analyze your plant layout, identify critical needs, and propose the most effective, safe, and goal-aligned spiral system.

Request your free check-up today and discover how to truly optimize your space and product flow.

![]()

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.