Today’s production lines demand increasingly high standards: higher speeds, lower noise levels, and greater safety.

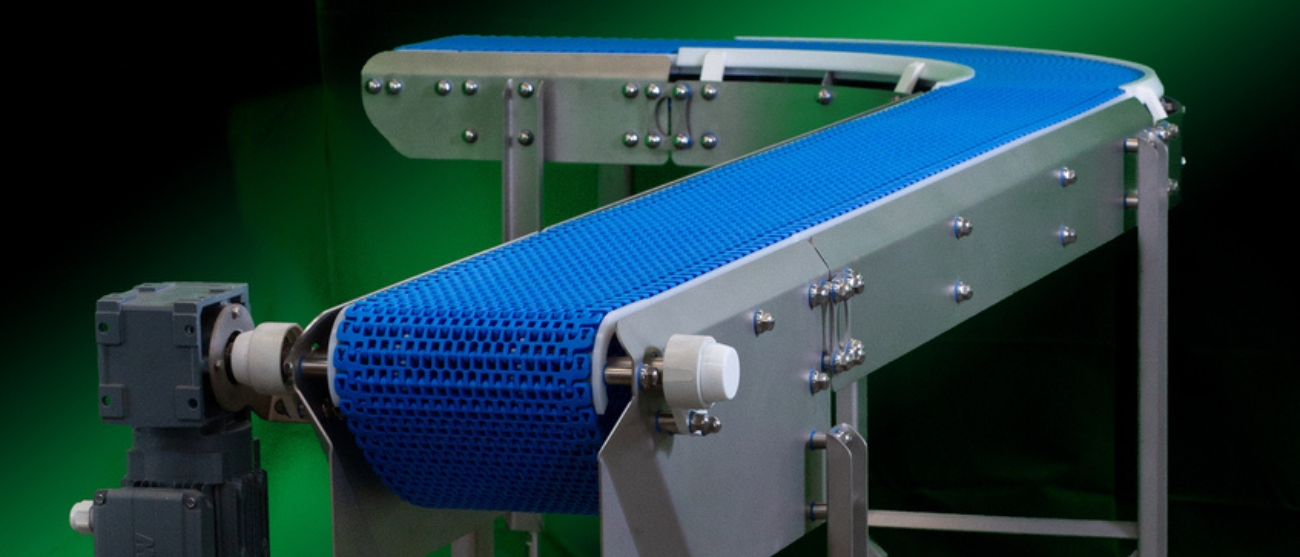

The historic 879 chain, developed in the late 1980s and established as an industry benchmark, has long proven its strength as a tireless “workhorse” of conveyor lines.

MH Material Handling decided not to settle.

Drawing on nearly forty years of experience and direct, ongoing dialogue with field technicians, USC – UltimateSafeChain was created: an evolution that preserves the robustness of the 879 while integrating with new technologies to meet the real demands of modern industry.

Can something that already works perfectly really be improved?

The strength of the 879 BAT has never been in question: robust, versatile, andlong-lasting, it has earned the trust of operators because it “simply works.”

In particular, tangential drive has proven over time to be the most effective solution for managing LIFO accumulation systems, such as the BAT Buffer, ensuring stability and operational continuity.

However, through extensive field experience and ongoing dialogue with technicians, a key insight emerged: when the foundation is solid, it can be made even safer, quieter, and more efficient.

For this reason, we partnered with Ammeraal Beltech, integrating Safety Finger technology into our new USC chain, a solution already recognized for its strong focus on operator safety.

USC: the reliability you’ve always trusted, even better performance

The new UltimateSafeChain is not a break with the past, but its natural evolution.

It is fully backwards-compatible with existing lines: no system redesign is required—only the chain and sprockets need to be replaced.

The tangible benefits are immediate:

- Higher operating speeds, increasing productivity without compromising stability.

- Reduced noise levels, improving operator comfort and supporting compliance with industrial noise regulations.

- Greater installable length, enabling more flexible and scalable system layouts.

- Enhanced stability and safety, thanks to the integration of Safety Finger technology, which reduces the risk of accidents and unexpected stoppages.

All of this while preserving what operators already know and value: the reliability of tangential drive, a distinctive feature that continues to deliver top performance in buffering and accumulation systems.

Easy revamping that reduces downtime and hidden costs

One of the most critical aspects of plant modernization is the risk of downtime. Stopping a production line to replace components slows productivity and increases operating costs.

USC was developed with a clear objective: to simplify revamping.

No complex rebuilds, no full replacement projects—just the new chain and the corresponding sprockets are enough to transform an existing system into a more modern, efficient, and safer solution.

This approach fully aligns with the Total Cost of Ownership (TCO) perspective: investing in next-generation components helps reduce hidden costs related to extraordinary maintenance, energy consumption, and unplanned downtime.

Why choose MH Material Handling

At MH Material Handling, every innovation is driven by listening to the real needs of industrial systems.

With USC, we chose to preserve what already works—the robustness and tangential drive of the 879 BAT—and enhance it with new technologies that address today’s requirements: higher speed, greater safety, lower noise, and improved efficiency.

This is not an “off-the-shelf” product, but a solution designed to last over time, reduce risk, and simplify the daily work of those who operate and maintain systems.

That is what sets us apart: transforming conveyors from simple components into true drivers of competitiveness for companies.

If the 879 BAT has been a cornerstone for nearly 40 years, USC – UltimateSafeChain marks the beginning of a new chapter: the same reliability, with higher performance.

Would you like to find out whether USC can make your line more efficient and safer without redesigning the system?

Contact us for a personalized consultation: together, we will assess how a simple upgrade can be turned into an immediate advantage.

![]()

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.