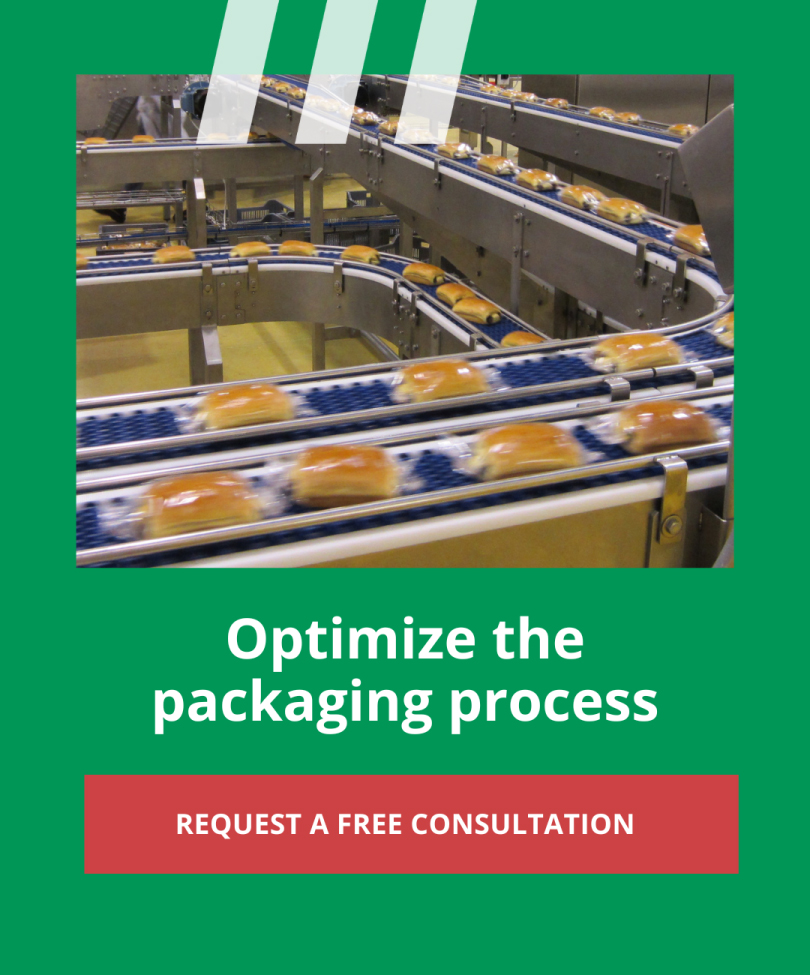

Packaging line automation represents a major opportunity to boost production efficiency, especially in emerging markets. However, to achieve real benefits, every phase of the process must be carefully planned.

In many facilities, automation stops at primary packaging, with downstream processes still relying heavily on manual labor. While this might seem like the easiest and quickest option, it limits productivity and scalability.

The implementation of new automated systems should not be improvised but must respond to a clear goal: reducing format variability and improving production flow. The temptation to rapidly replace manual operations with advanced machinery must be balanced with a critical consideration: the flexibility of human operators is difficult to replicate without substantial investment.

Planning Automation: Space, Ergonomics, and Logistic Connections

One of the most critical aspects of integrating new machines is managing the available space. It’s not just about the machine’s physical footprint, but also the area needed for operation, maintenance, and safe operator passage. From the start, it is essential to consider ergonomic implications: a line that hinders staff movement or access to equipment not only reduces efficiency but also increases the risk of accidents.

Furthermore, automation cannot be separated from warehouse logistics. Increasing productivity inevitably means more inbound and outbound material flow. Without an automated system for product handling and transport, bottlenecks may arise that cancel out the benefits of automation. Elevators, shuttles, and warehouse robotics are becoming indispensable to ensure operational continuity.

A Step-by-Step Approach: Why Phased Automation Works

Many companies, driven by the need to stay competitive, try to implement automation all at once. While this approach may seem faster and more effective, it carries several critical issues. A radical overhaul may cause weeks or months of production stoppage, significantly affecting operational costs and order fulfillment.

Instead, a gradual implementation allows each phase to be validated before moving forward. This approach minimizes errors, helps operators gradually adapt to new technologies, and ensures that each integration is optimized for the existing workflow.

The goal of well-structured automation is not only to boost productivity but also to ensure a smooth transition without compromising product quality or line organization.

M.H. Material Handling: Your Partner for Smart Automation

Transitioning to automation requires experience, expertise, and strategic vision. M.H. Material Handling supports companies in designing and implementing customized automation solutions that balance innovation, efficiency, and operational sustainability.

Through our MH Solution Scan service, we provide a detailed analysis of your packaging line to identify improvement areas and recommend the best solutions. If you’re considering automation to increase productivity and streamline flow management, contact us for a personalized consultation and discover how we can help you transform your production line into a high-efficiency, competitive system.

![]()

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.