The automation of packaging lines represents a strategic step for companies aiming to improve efficiency, reliability, and productivity. However, to ensure the success of an automation project, it is essential to find the right balance between production goals, financial resources, and structural constraints.

M.H. Material Handling, with nearly forty years of experience in the industry, has faced and resolved numerous challenges related to the integration of automated solutions, adapting them to the specific needs of its clients. In the following lines, we will analyze three key variables that determine the success of automation in packaging lines.

Industrial Automation: The Three Strategic Levers for Efficient Innovation

Production Goals

Defining production goals with precision, such as the number of products per minute or the ability to handle micro-stops, is the first step in developing an efficient line.

Each sector has specific requirements: for example, in the confectionery industry, seasonal lines such as those for chocolate need to be optimized to work at full capacity during winter months and reduce production capacity in summer. Planning based on demand allows for optimized investments and ensures maximum return from production facilities.

Financial Resources

Investing in automation does not necessarily mean building a complete system from the outset. A scalable approach allows for costs to be distributed over time, starting with an essential configuration and progressively expanding the line’s capabilities.

This strategy reduces risks, allows for adjustments based on market trends, and facilitates the adoption of new technologies without placing excessive strain on the company’s budget.

Operational Space

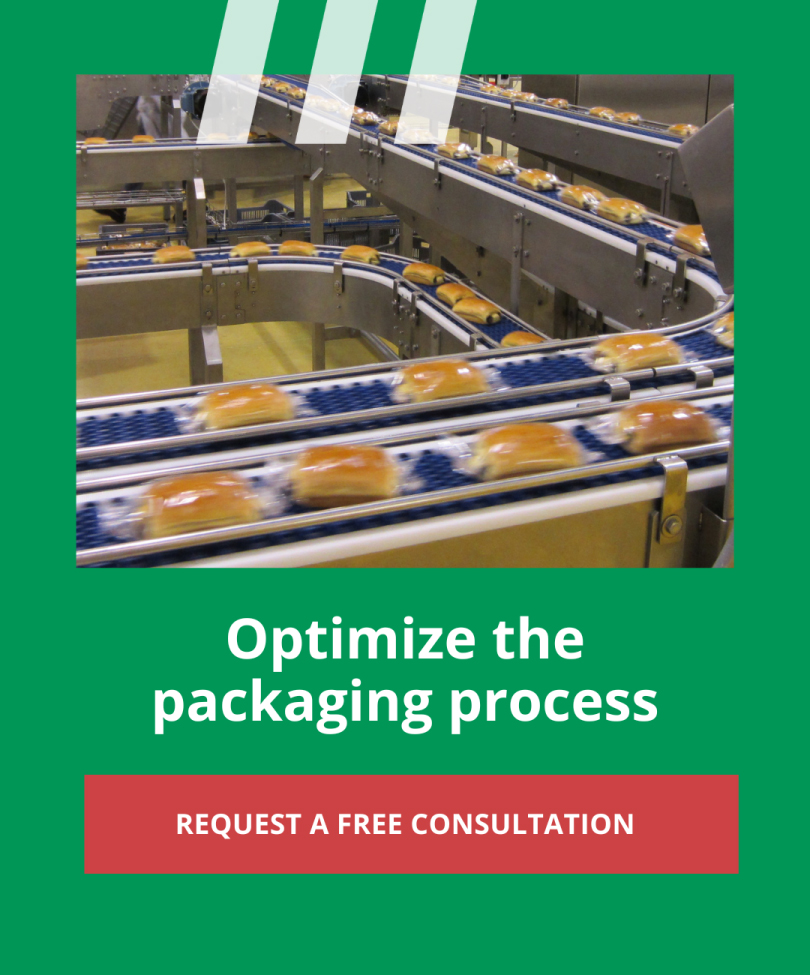

Optimizing available space is one of the most significant challenges in packaging line automation. Production plants, especially in Europe, face structural constraints that make intelligent use of space essential.

Innovative solutions such as spirals, elevators, and overhead conveyors allow for vertical development, reducing floor space usage and improving workflow organization.

Space and Productivity: Turning Every Square Meter into Operational Efficiency

Effectively managing production space is not just a matter of layout but a strategic factor that directly impacts productivity and reduces operating costs.

Overhead conveyors, for example, enable smooth connections between packaging and palletizing areas without compromising ground-level accessibility. However, when dealing with unpackaged products, it is essential to keep processing at the same level and within the same environment to maintain hygiene standards and facilitate product handling.

After primary packaging, multi-level solutions such as elevators and spiral buffers can fully optimize product distribution and improve line efficiency.

How to Integrate New Technologies into Existing Lines?

Integrating new technologies into existing packaging lines is a complex challenge that requires careful planning.

Each new addition must be designed to ensure a continuous production flow and avoid bottlenecks. An often-overlooked aspect is the connection between production lines and the warehouse: poor management can cause interruptions and compromise productivity.

Additionally, adding machinery or conveyor belts must be carefully studied to avoid obstructing operator movement and to facilitate maintenance operations.

For companies that cannot afford long production downtimes, the most effective strategy is to implement automation in phases, minimizing downtime and ensuring a smooth transition.

Automation and Growth: Looking Toward the Future

Investing in automated solutions does not only mean increasing productivity but also improving safety, reducing waste, and ensuring greater operational flexibility.

A well-designed system allows companies to quickly adapt to market changes, maintaining a competitive advantage.

To successfully transition to automation, it is essential to rely on industry-experienced partners like M.H. Material Handling, which offers customized solutions to optimize every phase of the production process.

Thanks to MH Solution Scan—our advanced analysis service—we can identify the weaknesses in your packaging line and propose targeted solutions to increase efficiency and productivity.

Discover how MH Solution Scan can transform your production line and make your company more competitive. Contact us for a personalized consultation.

![]()

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.