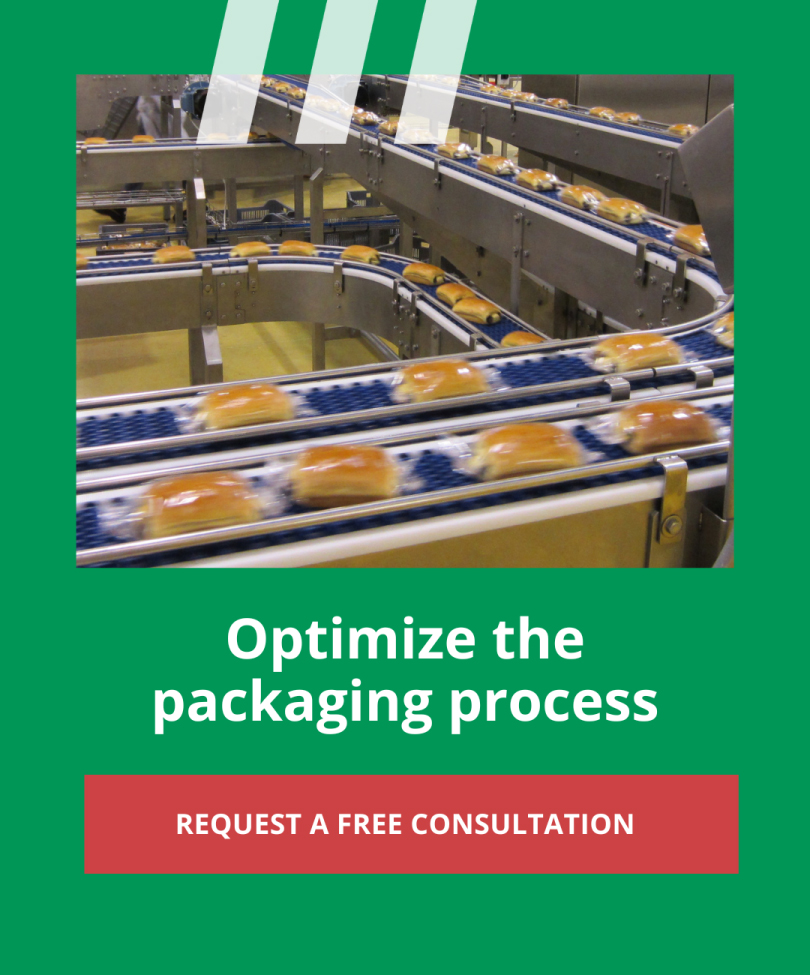

When a company needs to install a merge conveyor, there are a range of variables that make the decision a difficult one.

The need for a merge conveyor in a packaging line is itself enough to indicate a process with a very high degree of complexity and automation throughout.

Choosing the right merge conveyor means taking into account:

- how it protects the quality of the items;

- making sure the machines downstream work as intended;

- the efficiency of the entire packaging line.

It is clear therefore that mistakes could be critical.

The risk of ending up with an ineffective and obsolete packaging line is too high. That is why, whenever a client asks me which model is the best fit, I always start with a thorough analysis of their current operations, needs and expectations.

So, let’s start with a quick overview of these machines, explaining their purpose, their benefits and their limitations.

To start with, there are different types of merge conveyors, but the majority fall into one of two broad categories: mechanical (or buffer) merges and dynamic merges.

Buffer merges

This product is equipped with “gates” at the entry lanes that remain closed until the convergence area is free, at which point they let the items through one after the other.

This is a simple and cost-effective solution that works as long as two conditions are met:

- the items must be able to withstand the pressure during the buffering phase;

- the downstream machines must be able to receive the items in a convoy without being triggered to do so.

The first point is related to the integrity of the items, and essentially means that it is appropriate only for boxes, trays and products stacked in tight packaging.

The second point requires greater detail.

As they leave the merge, the items are touching each other, or very close to it, but the speed of the conveyor belt is the same as it would be with products that space out the items with one item’s worth of space between one and the next.

The average productivity of the line doesn’t change, but when the convoy arrives downstream, the machine’s productivity at that moment is doubled.

That is why the machine must be able to manage the flow, otherwise it is necessary to regulate the flow with one conveyor belt to increase the speed and another to decrease it after the merge; however, this solution is naturally bulkier, with two more motors and a more complicated logic controller.

Dynamic merges

When handling items that cannot be buffered for fear of overlap (generally pillow pouch or flowpack packaging) or damage caused by excessive pressure or because downstream machines need the items to arrive at a regular frequency and with a certain distance between one item and the next, then it becomes necessary to install a dynamic system.

A dynamic belt merge is a scalable system consisting of a series of modulating conveyor belts that increase or decrease the speed of the items as they come through, ensuring enough space to avoid a situation where two items reach the convergence point at the same time.

With these devices, the products are always handled one at a time, thereby avoiding having groups of items together and ensuring regular spacing. As the production pace increases, the number of modulators must also increase.

M.H. is an Italian brand with thirty years of experience with handling movement and logistics within production facilities in every sector of industry, with a range of solutions for buffer systems.

When it comes to dynamic merge conveyors, MH’s fastest system isthe HP dynamic system that can reach manufacturing of up to 600 ppm for 150mm flowpacks. Depending on the weight and packaging of the items, it is possible to use up to five phases of conveyors with brushless DC motor and vacuum suction to manage rapid acceleration.

Our wealth of experience means that M.H. is also able to support companies in optimising and streamlining their packaging lines with our innovative and technologically advanced solutions.

![]()

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.