Those who work with baked goods on a daily basis know all too well the critical importance of the packaging step.

Mistakes are not an option, and can lead to problems on the packaging line, compromising the integrity of the products and jeopardising the hard work done in preparing them.

All of these can lead to unplanned production downtime which, as you will know, potentially creates delays, problems and significant financial consequences.

Let’s begin by accepting the premise that often, especially in our country,food producers have two vital needs:

- maximising space, as the available surface area reserved for production — and especially packaging — is limited and precious;

- streamlining the packaging process as much as possible.

Taking these considerations into account, it is clear that conveyor belts have a vital role to play in packaging. The right conveyor belt can make all the difference.

So, let’s take a look at the different types of conveyor belts and when we might use them, taking into account that with baked goods it is worth distinguishing between different categories of products.

Regarding the cooling method, it can either be natural, in water (immersion or spray) or in a controlled environment (with dozens of different technological solutions available). The conveyor belts that make up the cooling system can be either spiral belts (adapted to reduce the necessary space for the cooling system), large conveyor belts or conveyors for baking trays.

Bread and dough products

When we talk about bread and dough products, they can take countless different forms: it goes without saying that each form has its own “rules” for conveying and packaging.

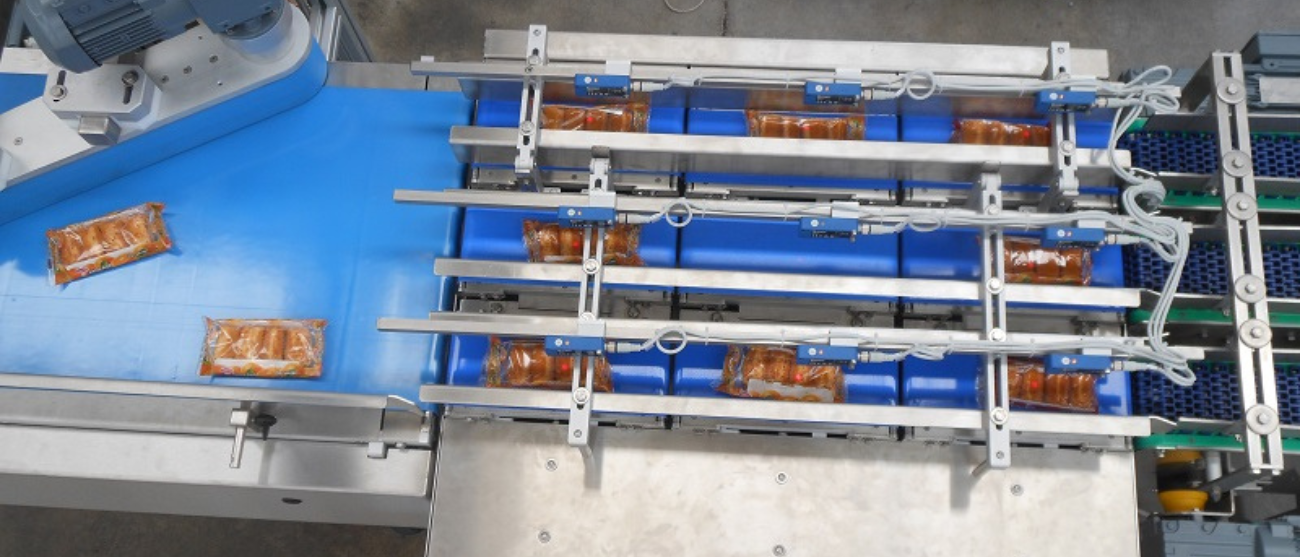

A recurring process requires a cooling system with a spiral conveyor followed by chicane aligners downstream that feed into the primary packaging machine.

The aligner consists of a series of wide belts with increasing speed, equipped with bulkheads and motorised diverters that channel the items through a series of chicanes that carry them through one or more neat lines.

The packaging machines could be either horizontal flowpacks, or vertical in the case of mini bread rolls, for example.

With Pullman sandwich loaves, the loaves pass through slicing machines that slice the bread before it’s packaged.

Bread in its various different forms very rarely comes in secondary packaging. It would far more commonly be placed directly in cardboard boxes or crates (depending on whether it is destined for large-scale retail or HoReCa). Here, merges and item layering systems may be useful, as they can naturally be buffered “with pressure”.

Crackers, rusks and biscuits

These goods require particular care and are always packaged in a stack, one on top of the other.

They therefore require special conveyor systems.

To meet this need, in the phase after cooling that usually takes place on wide conveyor belts, M.H. Material Handling has developed a dedicated line of FDA-certified conveyors with a modular plastic chain system for use in the food industry.

This solution offers significant benefits in terms of ease of use and maintenance compared to traditional belt systems. Thanks to its modular design, this type of belt guarantees extensive flexibility in designing the layout of the conveyor belts.

After this step, the goods are ready to be loaded as “packs” into the horizontal flowpack or wrapping machine.

Shortbread

As above, here too the cooling takes place on broad conveyor belts, but downstream the system that funnels the goods into the packaging machines varies greatly depending on the type of packaging required.

If the shortbread is individually packaged, they will have to be stacked one on top of the other; here too conveyor belts with a modular plastic chain offer the ideal solution.

However, if the shortbread is packaged in bags, the packaging machines funnel them in from above. Here we would recommend special conveyor belts that place the shortbread one on top of the other; there are then lift conveyor belts that load the shortbread onto weighing machines above the packaging machines.

Lift conveyor systems with modular chains are highly reliable and far easier to use and maintain than traditional bucket lift systems. They are ideal for continuous feeding of overhead lines[p1] , vertical packaging machines and multi-head weighing machines.

Cakes and pastries

Typical patisserie products, of the kind you might have for breakfast, are more durable than you might think.

They are cooled on spiral conveyors and packaged in horizontal flowpacks (as with bread, except with mini goods that are packaged vertically) and loaded using aligners.

These categories of goods are by far the most common within this sector; with certain exceptions, such as breadsticks, that have their own dedicated packaging lines.

Another scenario is that of frozen baked goods, as the presence of a constant level of humidity in the packaging line requires stainless steel conveyor belts that are resistant to corrosion and can be washed down.

As this brief overview has hopefully demonstrated, there are many factors to take into consideration and each category of baked goods has its own requirements. To complicate matters further, the precise specifications of the packaging machine impact the type of conveyors that work with them.

To optimise the packaging process of baked goods, you must be confident that the conveyor belts in use offer technologically advanced solutions that are also compatible with the packaging machines in the line.

M.H. is an Italian brand with thirty years of experience with handling movement and logistics within production facilities in every sector of industry, providing conveyor belts, merge and sort buffer systems, item rotators and flippers, lifts, destackers and other accessories necessary in the packaging and product manufacturing process.

Thanks to their modular design, M.H.’s products are interchangeable and easy to integrate into existing lines.

To find out more about how to improve the efficiency of the entire packaging process of your products, GET IN TOUCH TO DISCUSS.

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.

![]()