On this blog, I often discuss packaging process optimization and the machinery that can be installed to achieve this goal. Designing a line from scratch, perhaps even with ample space available, is one thing; intervening on an existing line with its mechanisms already in motion is another.

Is it still possible to optimize the process in these cases? Good question! The answer is yes, but there are multiple paths to take.

Today, I want to outline some solutions to this issue because more and more companies already have a packaging line but need to make it more efficient, both in terms of performance and ergonomics.

Recently, we’ve encountered many with this problem… just think of the contacts we made during Cibus Tec at the end of 2023.

What do these production realities need?

- To gain space in facilities where square meters are limited and often fully utilized.

- To increase packaging speed.

- To free up floor space and develop the process vertically (returning to point 1).

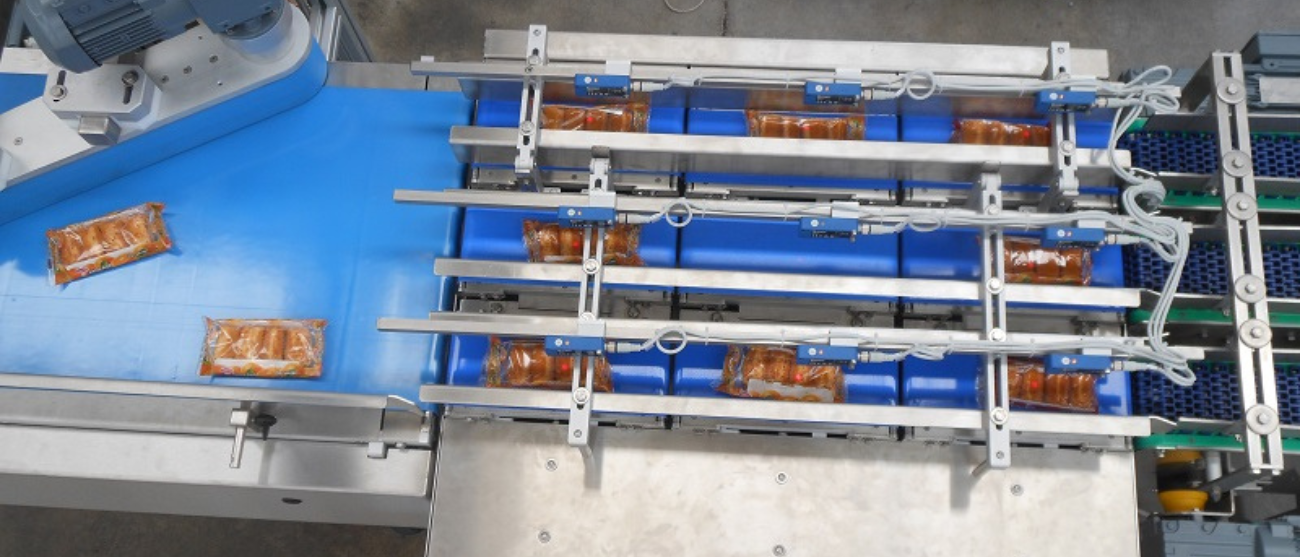

- To make the phase from primary to secondary packaging more efficient.

- To adapt to changes related to seeking greater sustainability in processes.

What are the solutions in these cases?

T o create overpasses and free up floor space, some technologically advanced solutions can be introduced, such as:

- Operator passages with gate-opening belts;

- Retractable systems;

- Spiral conveyors.

I want to focus on spiral conveyors because, in these cases, I consider them a valid solution.

It’s no coincidence that at Cibus Tec 2023, we presented the SVn-Bare lightweight spiral in collaboration with Ambaflex, specifically designed for agile aerial connections between primary and secondary packaging with significant economic advantage without compromising on quality and achievable peak speeds.

Another “powerful weapon” to improve the efficiency of packaging lines is represented by buffer systems; at MH, we can’t talk about them enough because they can really make a difference.

Buffer systems, for example, allow for:

- Compensating for operational differences between two machines connected in series;

- Regularizing the flow and preventing the processing line from constantly stopping;

- Recovering productivity in the event of micro-stops on downstream machines.

However, integrating a buffer system at a later stage into an existing line is not straightforward; this operation requires significant attention and a series of specific evaluations regarding the performance outcomes to be achieved.

Adaptations to environmentally friendly packaging.

Another highly topical issue leading companies to plan a series of investments to modify their packaging lines is the need to adapt to the use of low-environmental-impact packaging.

When I talk about “low-environmental-impact packaging,” numerous possibilities open up that include solutions aimed at reducing packaging material or actually replacing plastic with paper, cardboard, or compostable material.

In these cases, the packaging process must keep up with progress. And keep in mind that companies will increasingly have to deal with changes imposed by a search for sustainability in processes.

To this end, at M.H., we are continuously investing in research and development of products capable of offering customers innovative and sustainable solutions in line with new market needs and regulatory requirements.

For example, the Sani-Flex hygienic design transport system, our standard for the transport of naked products, is specifically designed to meet stricter regulations; Saniflex takes into account the sanitization needs of some products to help reduce bacterial load during the process.

Another example is our partnership with Intralox for the construction or development of special products such as spiral elevators, ThermoDrive belts, and passive ARB conveyors.

These mentioned are just some of the solutions designed by M.H. to support companies in the process of modernizing their packaging lines.

If you also need to make your lines more functional and efficient, do not hesitate to contact us; we will guide you on a path to optimizing productivity specifically tailored to your needs.

![]()

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.