At first glance, it may seem like a small detail, just a component connecting one machine to another, nothing more.

In reality, the conveyor is the heart of the line: efficiency, hygiene, safety, and ultimately the quality of the product reaching the consumer all depend on it.

Yet too often, its selection is underestimated, as if one belt were as good as another. But that’s not the case.

Each application is different, every product has its own characteristics, and each plant has its own criticalities.

Treating the conveyor as a “standard” element means opening the door to unexpected downtimes, contamination, waste, safety issues, and hidden costs that grow over time.

A significant share of line stops doesn’t stem from mechanical failures but from synchronization and accumulation problems, a clear sign that conveyors impact production continuity much more than people think.

When the product is “naked” fresh or dry is not enough

Talking about “naked” products means addressing very different worlds. A dry croissant is not the same as a honey-covered bar, just as a filled cake slice cannot be compared to a cracker.

In the fresh sector, hygiene is paramount. Belts must be washable, cavity-free and easy to sanitize. Belts with internal fabric layers are not suitable: if the fabric emerges, it becomes impossible to clean properly.

That’s why monolithic belts are used, more rigid and less flexible, but capable of ensuring the highest hygienic standards.

In the dry sector, the range is broader: brittle products such as biscuits or crackers fit well on modular chain conveyors, which allow easy removal of crumbs.

But when coatings, creams, or jams come into play, PU belts are required, surfaces that can be scraped clean without damaging the belt.

Each product type therefore requires a targeted evaluation.

Packaged products, but where in the line?

Even a packaged product raises specific questions: is it located in a white zone or a grey zone? Does it require washdown capability or not?

Are high speeds, tight transfers, or low noise levels needed?

In general:

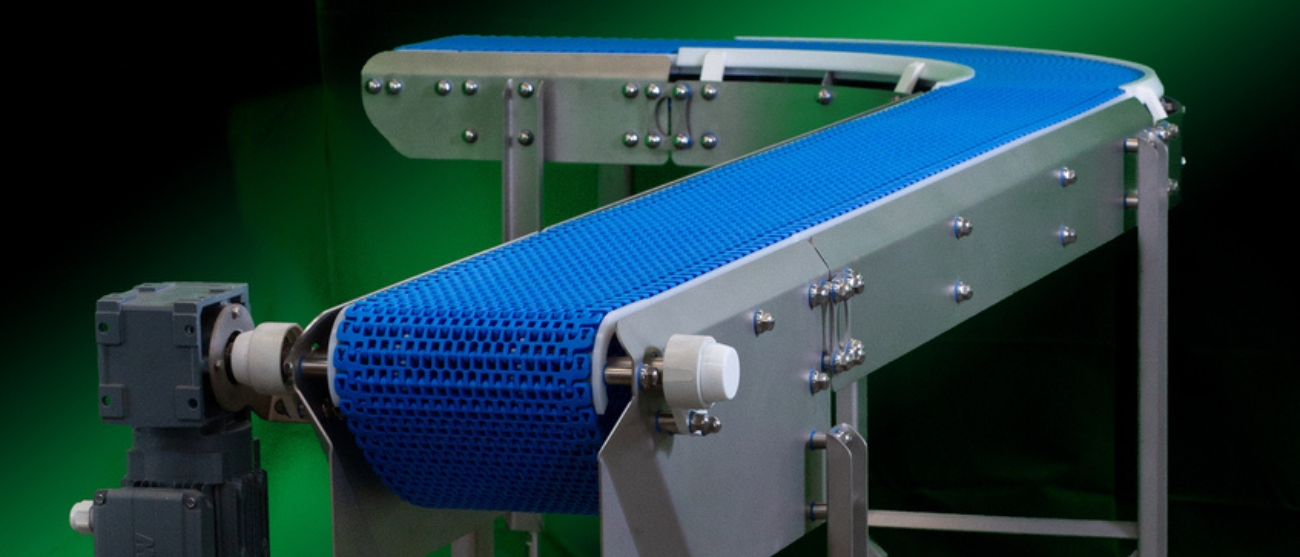

- The tabletop chain conveyor is ideal for heavy loads, high speeds, and complex layouts.

- The modular chain conveyor offers greater flexibility and smaller wrap diameters, but it’s less robust, has wider curve radii, and requires more maintenance attention.

If we’re in a washdown area, the structure matters too: at least the legs must be in stainless steel, if not the entire frame.

The choice, therefore, concerns not only the belt, but the whole operational context.

The invisible factors that make the difference

Beyond product features and packaging type, there are less visible but decisive variables:

Belt position

On the floor or overhead?

Overhead systems prioritize robustness, since maintenance interventions are more complex.

On-floor conveyors, instead, prioritize operator safety, requiring reduced-pitch chains to minimize risk.

Maintenance

How often will the belt need to be serviced? High frequency calls for easily removable and sanitizable designs.

Format variety

If the line handles multiple product types, flexible and adaptable systems are essential.

Finally, one basic principle must not be forgotten: machines never work in perfect synchronization. That’s why accumulation systems (buffers) are necessary to guarantee continuity and prevent line stops.

At M.H. Material Handling, we know these complexities well. For nearly forty years, we have been designing tailor-made conveyors for every type of line, product, and requirement – from fresh to packaged good.

Our solutions always start from listening: we don’t begin with a standard catalog, but with a real customer problem.

Whether it’s about handling a delicate product, freeing up floor space for operators, or optimizing flows in limited spaces, every project is co-designed together with the customer.

From the washdown SaniFlex line to the BAT system with USC chain, up to the ModulFlex conveyors with modular chains ,each technological choice follows a clear logic: transforming daily challenges into efficient, safe, and long-lasting solutions.

For us, automation doesn’t mean selling a machine, it means designing together the right answer to a real need.

Want to understand which solution best fits your line?

Contact us for a personalized consultation and discover how to make your system smoother, safer, and more efficient.

Co-Owner M.H. Material Handling Spa – For almost twenty years he has been working in the field of product handling during packaging, supporting companies that want to optimize the entire line. Always up-to-date on industry innovations and new materials, he makes his experience available to clients with the ultimate goal of eliminating interruptions and inefficiencies in the packaging process. Voracious reader, overnight writer and content creator.

![]()